Building a Wooden Kayak: A Complete Guide

Hey there, fellow water enthusiasts! Are you looking to take your paddling adventures to a whole new level? Building your own wooden kayak is a rewarding journey that combines woodworking skills with a touch of artistry. It's a chance to create something truly unique and personal, a vessel that reflects your own design and craftsmanship. So, grab your tools, get comfy, and let's dive into this exciting project!

Choosing Your Design and Materials

The first step in this adventure is picking the perfect kayak design. There are countless plans available online and in books, each offering its own unique characteristics and skill level. Consider the type of paddling you'll do, your experience level, and your preferred style. For beginners, a simple, traditional design like a Greenland kayak might be a good choice. More experienced builders might enjoy tackling a more challenging design, like a sea kayak with intricate curves.

Once you've settled on a design, you'll need to choose your wood. Some popular choices include:

- Cedar: Lightweight, rot-resistant, and beautiful with its natural red hue.

- Spruce: Strong and flexible, ideal for ribs and stringers.

- Oak: Durable and heavy, perfect for keel and stem.

- Mahogany: Elegant and luxurious, but also expensive.

The type of wood you choose will depend on your budget, the design, and your personal preferences. It's always a good idea to consult with experienced woodworkers or boat builders to get advice on choosing the right materials for your project.

Gathering Your Tools and Supplies

Building a wooden kayak requires a decent collection of tools. Here's a basic list to get you started:

- Hand saw: For cutting wood to size.

- Band saw: For intricate cuts and curves.

- Router: For shaping and smoothing edges.

- Sandpaper: Various grits for achieving a smooth finish.

- Clamps: For holding pieces together while gluing.

- Drill press: For drilling holes and creating mortise and tenon joints.

- Epoxy resin: For bonding wood pieces together.

- Fiberglass cloth: For adding strength and waterproofing.

- Paint or varnish: For a protective finish.

This list is just a starting point. The specific tools you'll need will depend on the design and your personal preferences. Don't be afraid to ask for help or advice from experienced boat builders or woodworkers, they can help you choose the right tools for the job.

Building the Framework: The Skeleton of Your Kayak

The framework, or skeleton, of your kayak is crucial for its shape and strength. It's built from the keel, stem, ribs, and stringers. Each piece is carefully cut and fitted together, creating a robust structure that will support the hull.

Laying the Keel

The keel is the backbone of your kayak, running along the center line of the hull. It's typically made from a strong hardwood like oak. Start by laying out the keel on your workbench and shaping its profile according to your design plans. Pay close attention to the curves and angles of the keel, ensuring it matches the plans precisely.

Joining the Stems

The stems, located at the bow and stern of the kayak, connect to the keel and provide a strong attachment point for the hull. Use strong adhesives and clamps to join the stems to the keel, creating a sturdy base for the framework.

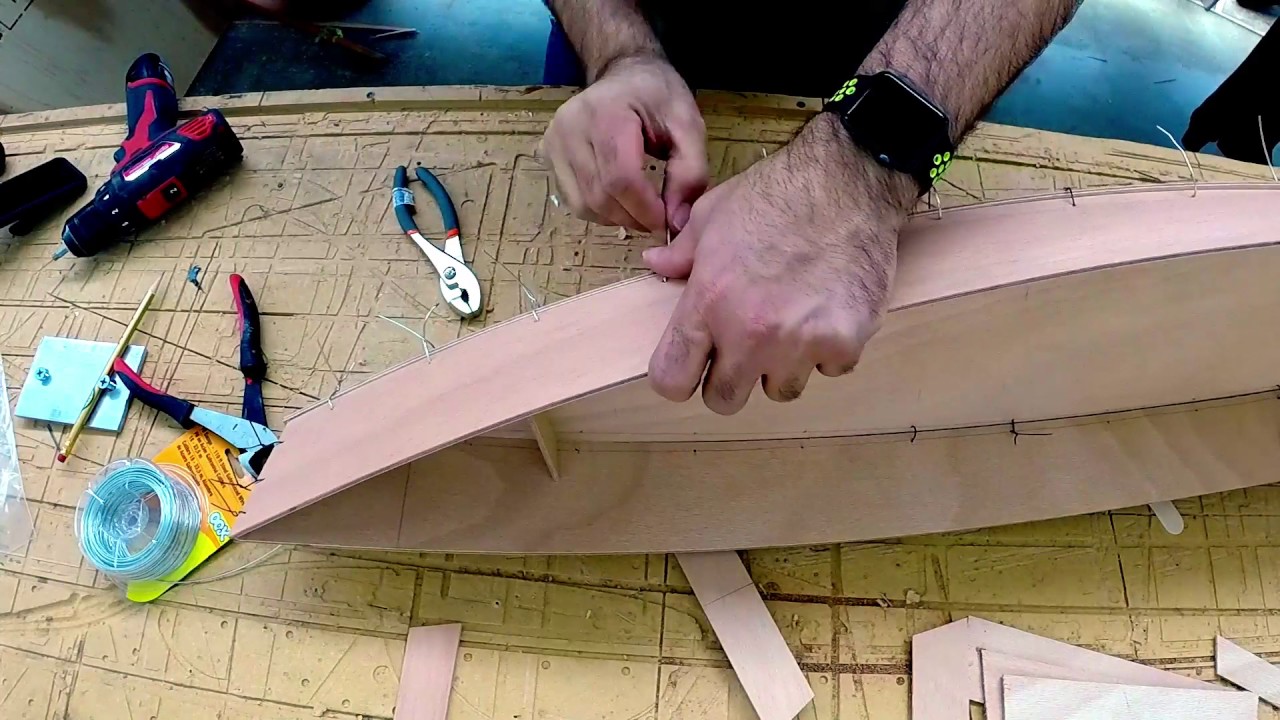

Constructing the Ribs

The ribs, usually made from spruce or cedar, provide the curved shape of the hull. They are spaced evenly along the keel and attached to the stems. Carefully cut each rib to match the curvature of the hull, ensuring they all fit smoothly against the keel and stems. Use mortise and tenon joints or other joinery techniques to securely attach the ribs to the framework.

Adding the Stringers

Stringers, also known as longitudinals, run along the length of the hull and provide additional strength and support. They are attached to the ribs, adding stability and helping to maintain the overall shape of the kayak. Carefully measure and cut the stringers to match the shape of the hull, ensuring they are correctly placed and securely attached to the ribs.

Creating the Hull: Shaping and Planking

With the framework complete, it's time to build the hull, the outer shell of your kayak. This involves shaping the planking, which are thin strips of wood that cover the framework, creating the smooth and watertight hull.

Planking the Hull

Planking is often done in strips, starting with the bottom and working your way up the sides. Use a combination of hand tools and power tools to carefully shape and fit the planking to the framework. Each plank should be meticulously cut to the curve of the hull, ensuring a smooth transition from one plank to the next. Secure the planking to the framework with strong adhesives and clamps.

Fine-Tuning the Hull

Once the planking is in place, use a router and sandpaper to smooth and shape the hull to achieve the desired profile. Carefully sand away any bumps or irregularities, creating a smooth and seamless surface for the final finish.

Adding Strength and Waterproofing

Before adding the final finish, it's crucial to ensure your kayak is strong and waterproof. This involves adding fiberglass cloth and epoxy resin.

Applying Fiberglass Cloth

Fiberglass cloth is woven into a mesh-like material that provides additional strength and stiffness. It's applied over the hull, covering the entire surface with overlapping layers. Cut the fiberglass cloth to fit the shape of the hull and saturate it with epoxy resin. Use a roller or brush to smooth out any air bubbles, ensuring the fiberglass is evenly distributed.

Adding the Finishing Touches

Once the fiberglass is completely cured, you can apply a final finish to your kayak. This can be paint, varnish, or even a natural oil finish. Choose a finish that provides protection from the elements and enhances the natural beauty of your wooden kayak.

Launch Day: The Moment of Truth

After weeks or even months of hard work, the day has arrived. It's time to launch your handmade wooden kayak into the water! Take a moment to admire your creation, knowing you've built something truly special and unique. As you glide across the water, you'll feel a sense of pride and accomplishment, knowing you've crafted a vessel that is not only beautiful but also a testament to your skills and dedication. Enjoy your journey!

Commonly Asked Questions

Building a wooden kayak is a journey, not a race. It's an adventure that will challenge you and reward you in equal measure. You'll learn new skills, discover hidden talents, and create a truly personal vessel. If you're passionate about paddling and woodworking, building your own wooden kayak is an experience you won't forget.

How much does it cost to build a wooden kayak?

The cost of building a wooden kayak can vary widely depending on the materials, design, and your level of DIY skills. You can expect to spend anywhere from a few hundred dollars to several thousand dollars on a wooden kayak project. Here are some factors that can affect the cost:

- Type of wood: Exotic hardwoods like mahogany or teak can be quite expensive.

- Design complexity: A complex design with intricate curves and details will require more materials and labor.

- Tooling: Some tools might need to be purchased, while others might be borrowed or rented.

- Fiberglass and epoxy: The amount of fiberglass and epoxy resin needed will depend on the size and design of the kayak.

With careful planning and budgeting, you can build a beautiful and functional wooden kayak within your budget.

How long does it take to build a wooden kayak?

The time it takes to build a wooden kayak depends on the design, your experience level, and how much time you can dedicate to the project. A simple kayak might take a few weeks to build, while a more complex design could take several months. It's important to be realistic about the time commitment involved and to break down the project into manageable steps.

Do I need any prior woodworking experience?

While it's helpful to have some woodworking experience, it's not strictly necessary to build a wooden kayak. There are plenty of resources available to help beginners learn the basics of woodworking. Start with a simple design and work your way up to more complex projects as you gain experience. Remember, patience, perseverance, and a willingness to learn are key to success in any woodworking project.

Building a wooden kayak is a journey of discovery, a fusion of art and craft. It's a chance to connect with nature, celebrate craftsmanship, and create a vessel that reflects your unique style and personality. So, take the plunge, embrace the challenge, and build your own wooden kayak!